OLED

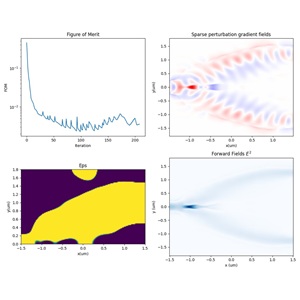

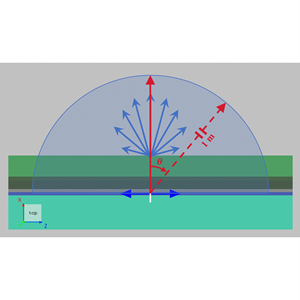

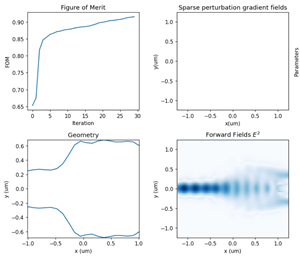

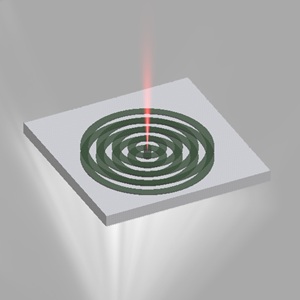

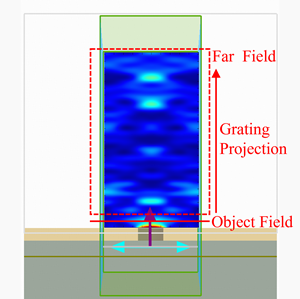

Organic light-emitting diode (OLED) devices are widely used in high-end displays and solid-state lighting due to their self-emissive nature, wide viewing angle, high contrast ratio, and compatibility with flexible form factors. A typical OLED consists of multiple organic functional layers and electrodes, with a total thickness usually on the sub-micrometer scale. In such a multilayer optical environment, radiation generated by dipole emitters in the emissive layer is strongly influenced by optical confinement and interference effects. In addition, refractive index discontinuities between functional layers cause a large portion of the emitted light to be trapped inside the device in the form of waveguide modes or surface plasmon polariton modes, so that only a small fraction can escape into air. As a result, accurate modeling of multilayer optical behavior, combined with micro- and nanostructure design to enhance light extraction efficiency (LEE), is a key challenge in OLED optical design. In this case, a 2D FDTD method is used to model an OLED device. By comparing structures without microstructures and with periodic microstructures (photonic crystals), the effect of microstructure design on LEE is evaluated.

details

2026-01-29 14:34:51

Enterprise WeChat

Enterprise WeChat WeChat Service Account

WeChat Service Account

Wechat Channels

Wechat Channels