Preface

With the development of optical design and engineering applications, there is a growing demand for lightweight, compact lens components that still provide high focusing capability. Traditional convex lenses often become thick, heavy, and expensive to manufacture when designed for short focal lengths and large apertures, making them difficult to use in systems with strict constraints on size, weight, and cost. By employing a distinctive “concentric stepped ring” structure, the Fresnel lens decomposes the continuous surface of a conventional lens into multiple “annular micro-lenses,” each functioning as an independent refracting surface. This design dramatically reduces the lens thickness and mass while maintaining focusing or imaging performance comparable to that of a traditional convex lens. Because of this thin and lightweight architecture, Fresnel lenses are widely used in lighthouse illumination, projection systems, solar concentrators, and compact imaging devices—particularly in applications where high focusing efficiency is required under tight volume and cost constraints.

In this case, a 2D FDTD simulation is performed for a Fresnel lens derived from a spherical lens profile, demonstrating its wavefront-shaping capability and characteristic phase behavior.

Simulation settings

Structure

The Fresnel lens used in this case is derived from a simple spherical lens model with a radius of curvature and an aperture of . The lens material has a refractive index of and is placed in air. For a conventional convex lens, the ideal surface profile is:

When light passes through a lens region of height , it acquires an additional phase delay:

When , the phase delay introduced by the lens is exactly , making the optical effect fully equivalent to that before passing through the lens. This allows the continuous lens surface to be compressed into a finite-height concentric ring structure through this “phase wrapping” approach.

For the operating wavelength used in this case ( ), the corresponding wrapping height is . Based on this, the surface profile of the Fresnel lens in this case can be expressed as:

The FresnelLens.txt file provides the point-array data for this surface and can be used to create the structure through the Import Surface feature. For details, see Surface Import.

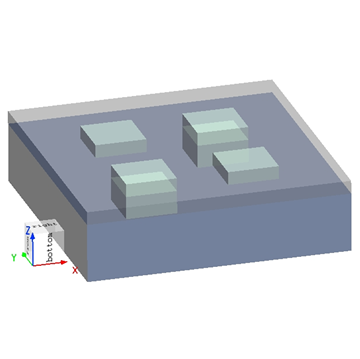

Because the lens spans laterally but has a height of only , it is difficult to visualize clearly in the composite view. Therefore, the figure below shows the index_y distribution at the wavelength of , where the constructed lens structure can be clearly seen to match the design.

Simulation results

When a plane wave is normally incident on the lens, the wavefront is modulated by the lens and gradually evolves into a spherical-wave profile. The figure below shows the propagation of the electric field component , where the initially flat wavefront progressively bends and converges toward the focal point, confirming the focusing capability of the Fresnel lens.

The transmitted field intensity is obtained from the FDFP monitor placed behind the lens, as shown below. Due to the discontinuities on the lens surface, sharp lines appear in the field distribution—a typical characteristic of Fresnel lenses.

The phase of the transmitted electric field is shown below. When a discontinuity appears in the lens structure, a characteristic phase jump appears. Overall, the phase curve exhibits a smooth quadratic trend, indicating the spherical wavefront converging toward the focal point.